+86 17737144966

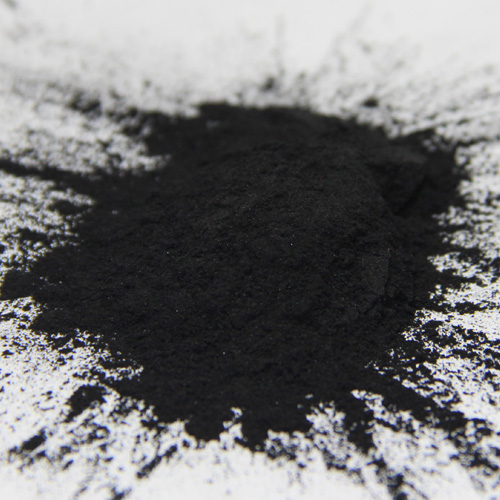

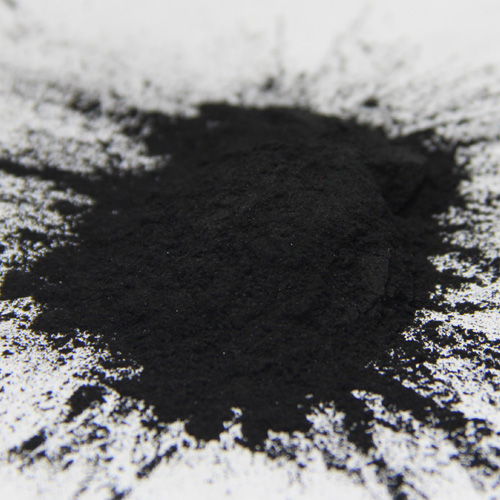

Coal powder is made from anthracite as raw material and is refined by steam method in various processes. The main components of coal powder activated carbon include oxygen, hydrogen and other elements in addition to carbon. Because of the irregular arrangement of microcrystalline carbon in the structure of this product, there are fine pores between the cross connections, and carbon structure defects will occur during activation, so it is a porous carbon with low bulk density and large specific surface area. Various substances and impurities larger than the color in the adsorption liquid.

Different activated carbon">activated carbons have different adsorption properties. The production raw materials of activated carbon for water treatment include wood, nut shell, anthracite, petroleum coke, etc. The production process is mostly physical method, and is produced by activation furnaces such as Slip furnace, rake furnace, converter furnace, and boiling furnace. Due to different raw materials, different production process conditions, different pore sizes of activated carbons, different specific surface areas, and different surface chemical compositions and chemical properties, the adsorption performance is different.

Common specifications: 80 mesh, 120 mesh, 200 mesh, 325 mesh:

Methylene blue decolorization power(ml/g) | ≥150 | ≥160 | ≥170 | ≥180 | ≥200 |

Iodine adsorption value(%) | ≥900 | ≥950 | ≥1000 | ≥1050 | ≥1100 |

PH | 9-11 | 9-11 | 9-11 | 9-11 | 9-11 |

loss on drying(%) | ≤10 | ≤10 | ≤10 | ≤10 | ≤10 |

total iron salts(%) | ≤0.1 | ≤0.1 | ≤0.05 | ≤0.05 | ≤0.05 |

burning residue(%) | ≤6 | ≤6 | ≤6 | ≤5 | ≤5 |

chloride(%) | ≤0.5 | ≤0.5 | ≤0.5 | ≤0.5 | ≤0.5 |

specific conductivity(hs/cm) | ≤900 | ≤900 | ≤700 | ≤700 | ≤700 |

Phenol value(%) | <25 | <25 | <25 | <25 | <25 |

ABS(%) | <50 | <50 | <50 | <50 | <50 |

arsenic(wtppm) | <1 | <1 | <1 | <1 | <1 |

lead(wtppm) | <10 | <10 | <10 | <10 | <10 |

Zinc(wtppm) | <30 | <30 | <30 | <30 | <30 |

cadmium(wtppm) | <1 | <1 | <1 | <1 | <1 |

Particle size 200 mesh pass rate(%) | ≥90 | ≥90 | ≥90 | ≥90 | ≥90 |

Coal powder activated carbon is mainly used in oil, dye, chemical industry, tap water purification, industrial sewage treatment, COD reduction, BOD and other purposes.

On the basis of the conventional water treatment process, the process flow of adding powdered activated carbon to remove micro-pollution is shown in the figure below.

The powdered activated carbon is made into carbon slurry with a concentration of 5%. The carbon slurry is a mixed liquid, and the sedimentation speed is very fast, so it is necessary to continuously stir the carbon slurry while adding the carbon slurry.

Add the carbon slurry before the mixing tank, mix it with the raw water in the mixing tank, absorb the pollutants in the water in the flocculation tank and the sedimentation tank, and attach to the flocs, and precipitate together in the sedimentation tank. Powdered activated carbon particles can be removed in the filter to achieve the purpose of removing micro-pollution. The dosage of powdered activated carbon can be determined flexibly with the change of the pollution degree of raw water.

Coal based powdered activated carbon matters needing attention:

1. During transportation, coal-based powdered activated carbon should be prevented from being mixed with hard substances, and should not be stepped on or stepped on to prevent the carbon particles from being broken and affecting the quality.

2. Coal powder activated carbon is a porous adsorbent, so during transportation, storage and use, it must be absolutely prevented from water immersion, because after water immersion, a large amount of water fills the active voids, making it useless.

3. To prevent tar substances from being brought into the coal powder activated carbon bed during the use process, so as not to block the activated carbon gap and make it lose its adsorption effect.

Coal based powdered activated carbon factory packaging and storage:

25kg/bag (packed in woven bag, lined with polyethylene plastic film).

Packaging can be customized according to customer needs.